Tire Construction: Understanding the Basics

Tire construction is a complex process that involves the use of various materials and advanced engineering techniques. Tires are an essential component of any vehicle, providing a comfortable and safe ride while also ensuring optimal performance. Understanding tire construction is crucial for anyone who owns a vehicle, as it can help you make informed decisions when choosing the right tires for your needs.

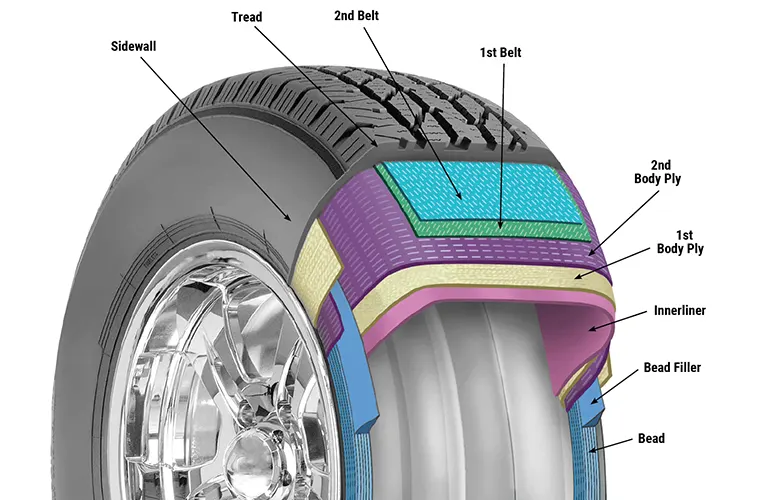

Tire construction involves several key components, including the inner liner, carcass ply, sidewall, bead, and tread. Each of these components plays a critical role in ensuring the tire's overall performance and durability. In addition, the tire's design and structure can also impact its performance characteristics, such as handling, traction, and fuel efficiency. Understanding these factors can help you choose the right tires for your vehicle and driving needs.

Key Takeaways

- Tire construction is a complex process that involves the use of various materials and advanced engineering techniques.

- Tires consist of several key components, including the inner liner, carcass ply, sidewall, bead, and tread, each of which plays a critical role in ensuring the tire's overall performance and durability.

- The tire's design and structure can also impact its performance characteristics, such as handling, traction, and fuel efficiency, making it essential to choose the right tires for your vehicle and driving needs.

Tire Basics

When it comes to tires, there are a few basic things that everyone should know. In this section, we will cover the main components of a tire and their functions.

Parts of a Tire

A typical tire consists of six main parts: the tread, sidewall, bead, carcass, belts, and inner liner. Each of these parts plays a crucial role in the tire's performance and durability.

-

Tread: The tread is the part of the tire that comes into contact with the road. It is designed to provide traction and grip in different weather and road conditions.

-

Sidewall: The sidewall is the part of the tire that connects the tread to the bead. It provides the tire with lateral stability and protects it from damage.

-

Bead: The bead is the part of the tire that sits on the rim. It is made of high-strength steel wire and provides the tire with a secure fit on the rim.

-

Carcass: The carcass is the foundation of the tire. It is made of layers of rubber-coated fabric and provides the tire with its shape and strength.

-

Belts: The belts are layers of steel or synthetic fibers that are wrapped around the carcass. They provide the tire with additional strength and stability.

-

Inner Liner: The inner liner is a layer of rubber that is placed inside the tire. It provides an airtight seal and prevents air from escaping.

Tire Construction

Tires are constructed using a complex process that involves mixing various materials, molding them into shape, and curing them under heat and pressure. The exact process can vary depending on the type of tire and the manufacturer.

One important thing to note is that not all tires are created equal. Different tires are designed for different purposes and perform differently in different conditions. It is important to choose the right tire for your vehicle and driving needs to ensure optimal performance and safety.

Overall, understanding the basics of tire construction can help you make informed decisions when it comes to choosing and maintaining your tires.

Materials in Tire Construction

When it comes to tire construction, several materials are used to create a tire that can perform under a range of conditions. Here are some of the primary materials used in tire construction:

Rubber Compounds

Rubber is a crucial component of tire construction, and different types of rubber are used to create different parts of the tire. For example, natural rubber is used in the tread to provide grip and reduce wear, while synthetic rubber is used in the sidewall to provide durability and resistance to cracking. Other rubber compounds may be added to the tire to improve its performance in specific conditions, such as winter tires that include special compounds to improve traction on snow and ice.

Steel Belts

Steel belts are used in the tire to provide additional strength and durability. The belts are made up of several layers of steel cord that are wrapped around the tire's circumference. The steel belts help to reinforce the tire, providing stability and preventing the tire from deforming under pressure. This is especially important for high-performance tires that are designed to withstand high speeds and heavy loads.

Textile Plies

Textile plies are layers of fabric that are used in the tire to provide additional strength and support. The plies are typically made of materials such as polyester, nylon, or rayon, and they are layered in a criss-cross pattern across the tire's circumference. This helps to reinforce the tire and prevent it from deforming under pressure. Textile plies are also used to provide additional cushioning and improve ride comfort.

In conclusion, tire construction is a complex process that involves several different materials. By using a combination of rubber compounds, steel belts, and textile plies, tire manufacturers can create tires that can perform under a range of conditions and provide the necessary strength, durability, and comfort.

Tire Design and Structure

When it comes to tire design and structure, there are several key components that make up a tire's construction. In this section, we will discuss the three main sub-sections of tire design and structure: Tread Patterns, Sidewall Design, and Bead Construction.

Tread Patterns

The tread pattern of a tire is designed to provide traction, handling, and durability. A tire's tread pattern can vary depending on the intended use of the tire. For example, a tire designed for off-road use will have a more aggressive tread pattern than a tire designed for highway use.

Tread patterns can also be designed to provide specific benefits. For example, a tire with a directional tread pattern is designed to provide excellent water evacuation, making it ideal for wet road conditions. A tire with a symmetric tread pattern is designed to provide a smooth and quiet ride.

Sidewall Design

The sidewall of a tire is the part of the tire that connects the tread to the bead. The sidewall is also where you can find important information about the tire, such as the tire size, load index, and speed rating.

Sidewall design can vary depending on the intended use of the tire. For example, a tire designed for off-road use will have a thicker sidewall to provide added protection against punctures and cuts. A tire designed for highway use will have a thinner sidewall to provide a smoother ride.

Bead Construction

The bead of a tire is the part of the tire that sits on the wheel rim. The bead is made up of steel wires that are coated in rubber. The bead is designed to provide a secure fit between the tire and the rim.

Bead construction can vary depending on the intended use of the tire. For example, a tire designed for high-performance use will have a stiffer bead to provide better handling and stability. A tire designed for off-road use will have a more flexible bead to provide better traction and to help prevent the tire from becoming dislodged from the rim.

Manufacturing Process of Tires

Tire manufacturing is a complex process that involves several steps. In this section, we will discuss the various stages of tire production, including Mixing and Building, Curing, and Inspection.

Mixing and Building

The first step in tire manufacturing is mixing the raw materials. This process involves blending natural and synthetic rubber with various chemicals, oils, and carbon black. The resulting mixture is called a compound, which is then formed into sheets and cut into strips.

After the compound is prepared, the building process begins. This involves assembling the tire components, including the bead, ply, belt, and tread. The bead is the part of the tire that attaches to the rim, while the ply is the layer of fabric that provides strength and flexibility. The belt is a layer of steel or fabric that reinforces the tread, and the tread is the part of the tire that comes into contact with the road.

Curing and Inspection

Once the tire components are assembled, the tire is placed in a mold and cured under heat and pressure. This process causes the rubber to vulcanize, or harden, and bond the various components together. After curing, the tire is removed from the mold and inspected for defects.

Inspection is a critical part of the tire manufacturing process. Any defects, such as bubbles, cracks, or unevenness, can compromise the tire's safety and performance. Therefore, tires undergo rigorous testing to ensure they meet industry standards for quality and safety.

In conclusion, tire manufacturing is a complex process that involves several stages, including mixing and building, curing, and inspection. Each stage is critical to the tire's performance, durability, and safety. By following strict quality control procedures and using advanced technology, tire manufacturers can produce high-quality tires that meet the needs of drivers around the world.

Types of Tires

When it comes to tires, there are several types available in the market. Each type is designed for specific purposes, and it is essential to choose the right tire for your vehicle. In this section, we will discuss two types of tires: radial tires and bias tires.

Radial Tires

Radial tires are the most common type of tire used in modern vehicles. They are designed with steel belts that run perpendicular to the tire's direction of travel. These belts help the tire maintain its shape, provide stability, and improve fuel efficiency. Radial tires have a longer lifespan than bias tires and offer a smoother ride.

One of the main advantages of radial tires is their ability to dissipate heat. The steel belts in radial tires reduce heat buildup, which helps extend the life of the tire. Radial tires also have a larger contact patch with the road, which improves traction and handling.

Bias Tires

Bias tires, also known as cross-ply tires, are an older type of tire design. They are constructed with layers of fabric that run diagonally across the tire's tread. Bias tires have a stiffer sidewall than radial tires, which makes them ideal for heavy-duty applications such as off-road driving.

One of the main advantages of bias tires is their ability to carry heavy loads. The stiff sidewalls provide additional support, making them ideal for trucks and other heavy vehicles. Bias tires also have a higher resistance to cuts and punctures, which makes them suitable for off-road driving.

However, bias tires have several disadvantages compared to radial tires. They have a shorter lifespan, provide a rougher ride, and are less fuel-efficient. Bias tires are also more prone to heat buildup, which can lead to tire failure.

In summary, both radial and bias tires have their advantages and disadvantages. Radial tires are more common and offer a smoother ride, while bias tires are ideal for heavy-duty applications. It is essential to choose the right tire for your vehicle based on your specific needs and driving conditions.

Tire Performance Characteristics

When it comes to tire performance, there are several characteristics that we must consider. In this section, we will discuss the three main factors that affect tire performance: Traction, Durability, and Fuel Efficiency.

Traction

Traction is the tire's ability to grip the road surface. It is essential for safe driving, especially in wet or slippery conditions. The tire's tread pattern, rubber compound, and design all play a vital role in providing good traction.

Tread patterns with deep grooves and sipes help to channel water away from the tire's contact patch, reducing the risk of hydroplaning. A softer rubber compound can also improve traction, but it may wear out faster than a harder compound.

Durability

Durability is another essential factor to consider when choosing tires. A durable tire can withstand wear and tear, punctures, and other road hazards. The tire's construction, materials, and design all contribute to its durability.

Tires with stronger sidewalls can resist punctures and cuts, while those with reinforced belts can withstand heavy loads and high speeds. The tread compound also plays a role in the tire's durability, as a harder compound can last longer than a softer one.

Fuel Efficiency

Fuel efficiency is becoming an increasingly important factor in tire performance. A tire's rolling resistance affects its fuel efficiency, as it determines how much energy is required to move the tire. Tires with lower rolling resistance require less energy, which can result in better fuel economy.

Tires with silica-based compounds can reduce rolling resistance, as can those with optimized tread designs. However, it's important to note that tires with lower rolling resistance may sacrifice some traction and durability.

In conclusion, when it comes to tire performance, we must consider several factors. Traction, durability, and fuel efficiency are three of the most important characteristics to keep in mind when choosing tires. By understanding these factors, we can make informed decisions that will help us stay safe on the road and save money on fuel costs.

Tire Maintenance and Safety

When it comes to tire maintenance and safety, there are a few key things to keep in mind to ensure optimal performance and safety on the road or job site. Here are some dos and don'ts to follow:

-

Do inspect your tires regularly: Regular inspections can help you catch any issues early and prevent more serious problems down the line. Look for signs of wear and tear, such as cracks, cuts, and bulges, and check your tire pressure regularly to ensure it's at the recommended level.

-

Don't overload your tires: Overloading your tires can put unnecessary stress on them and increase the risk of a blowout. Make sure you know the weight limits for your tires and stay within them.

-

Do rotate your tires regularly: Rotating your tires can help ensure even wear and extend their lifespan. Check your vehicle's owner's manual for recommended rotation intervals.

-

Don't mix and match tire components: Mixing and matching tire components can compromise their safety and performance. Always use the same type of tire on all four wheels and never mix radial and bias-ply tires.

-

Do replace your tires when necessary: Don't try to squeeze extra life out of your tires if they're worn or damaged beyond repair. Replace them promptly to ensure your safety on the road or job site.

By following these simple guidelines, you can help ensure the safety and longevity of your tires, and reduce the risk of accidents or breakdowns.

Environmental Impact of Tires

Tires are an integral part of our daily lives, but the environmental impact of tires is often overlooked. The production, use, and disposal of tires have significant environmental consequences. In this section, we will discuss the various environmental impacts of tires.

Production

The production of tires involves the use of various chemicals and materials, including natural rubber and synthetic rubber, carbon black, and various chemicals. The production of these materials requires significant amounts of energy and water, which can have environmental consequences. Additionally, the production of tires generates significant amounts of waste, including scrap rubber and other materials.

Use

The use of tires has significant environmental impacts, primarily through the emission of greenhouse gases. The rolling resistance of tires generates friction, which requires additional energy from the engine to overcome. This additional energy results in increased fuel consumption and emissions of greenhouse gases, such as carbon dioxide. Additionally, the wear and tear of tires generate microplastics that can enter the environment and harm wildlife.

Disposal

The disposal of tires is a significant environmental concern. Many tires end up in landfills, where they can take hundreds of years to decompose. Tires can also be burned, which can release toxic chemicals into the air. The improper disposal of tires can also lead to the accumulation of water, which can create breeding grounds for mosquitoes and other pests.

Recycling

Recycling tires can help reduce their environmental impact. Tires can be recycled into a variety of products, including rubberized asphalt, playground surfaces, and athletic tracks. Recycling tires can also reduce the need for new materials, which can help conserve natural resources and reduce energy consumption.

In conclusion, the environmental impact of tires is significant and multifaceted. From production to disposal, tires have the potential to harm the environment. However, recycling tires can help reduce their impact and promote sustainability.

Innovation and Future of Tires

As tire manufacturers, we understand the importance of innovation and the need to keep up with the ever-changing demands of the market. The tire industry has come a long way since its inception, and we are continuously looking for ways to improve our products. In this section, we will discuss some of the latest innovations in tire technology and what the future holds for the industry.

One of the most significant advancements in tire technology is the use of new materials. For example, the use of silica in tire compounds has resulted in better grip and fuel efficiency. Additionally, the use of nanotechnology has allowed for the development of stronger and more durable tires. We are also exploring the use of sustainable materials, such as natural rubber, to reduce our environmental impact.

Another area of innovation is tire design. We are constantly developing new tread patterns and tire shapes to improve performance in various conditions. For example, run-flat technology allows drivers to continue driving even after a puncture, reducing the risk of accidents and improving safety. Additionally, the use of digital simulation software has allowed us to test new designs in real-world conditions before manufacturing them.

In the future, we see the tire industry moving towards increased automation and digitization. The use of sensors and data analysis will allow for real-time monitoring of tire performance and predictive maintenance. We also expect to see the development of smart tires that can communicate with the vehicle and adjust to changing road conditions.

Overall, we are confident that the future of the tire industry is bright. We will continue to invest in research and development to ensure that our products meet the evolving needs of our customers while also reducing our environmental impact.

Frequently Asked Questions

What are the three main materials used in tire construction?

The three main materials used in tire construction are rubber, fabric, and steel. Rubber is used for the tire's tread and sidewalls, while fabric is used for the tire's body plies and belts. Steel is used for the tire's belts and bead wire.

What is the most common type of tire construction?

The most common type of tire construction is radial. In radial tires, the plies run radially across the tire from bead to bead, with the cords at a 90-degree angle to the direction of travel. This design offers improved handling, longer tread life, and better fuel efficiency compared to bias-ply tires.

What are the two types of tire construction?

The two types of tire construction are bias-ply and radial. In bias-ply tires, the plies run diagonally across the tire, with the cords at an angle to the direction of travel. This design offers durability and load-carrying capacity, but at the expense of handling, ride quality, and fuel efficiency.

How are tires made step by step?

Tires are made through a complex process that involves various stages, including mixing, extrusion, calendaring, building, curing, and inspection. The process begins with mixing various raw materials, such as rubber, carbon black, and chemicals, to create a rubber compound. The compound is then extruded into various shapes and sizes, such as tread strips and sidewalls. The strips are then calendared to give them the desired thickness and texture. The building process involves assembling the various components of the tire, including the plies, belts, and tread. The tire is then cured in a mold under heat and pressure to give it its final shape and properties. Finally, the tire is inspected for quality and defects before being shipped to the customer.

What is the anatomy of a tire valve stem?

A tire valve stem is a small but important component of a tire. It consists of a metal or rubber stem that protrudes from the wheel and a valve core that controls the flow of air in and out of the tire. The valve stem is typically made of brass or aluminum and is attached to the wheel through a mounting hole. The valve core is a small, spring-loaded device that can be removed to inflate or deflate the tire.

What are tire belts and their function?

Tire belts are layers of fabric or steel that are embedded in the tire's tread area to reinforce it and provide stability. They help to distribute the load evenly across the tire's surface, which reduces wear and improves handling. The belts also help to prevent punctures and other types of damage to the tire's tread. The number and type of belts used in a tire depend on its intended use and performance requirements.